6mm Welded Link Rantai, Coal Mining/Mining/Tambang Rantai, Baja Karbon Komersial

6mm Welded Link Rantai, Coal Mining/Mining/Tambang Rantai, Baja Karbon Komersial

kategori

Rantai link bulat, rantai link baja bulat, rantai pertambangan link bulat, DIN 22252rantai pertambangan, rantai conveyor pertambangan, sistem rantai bar penerbangan

Aplikasi

Armored Face Conveyors (AFC), Beam Stage Loaders (BSL), mesin header dalan, bajak batubara, lsp.

Minangka negara produksi batu bara No. pabrik chain SCIC kang karo 30 taun babak baja link chain sajarah produksi wis kebak melu menyang China sumber industri batu bara; chain link babak kita wis dadi adoh uga ditampa lan digunakake dening kabeh coal utama & perusahaan pertambangan liwat China.

Kualitas rantai link baja bunder kita dijamin liwat saben langkah produksi rantai, saka bar baja paduan swara nganti fabrikasi link sing tepat dening robot, saka welding lampu kilat komputerisasi nganti quenching & tempering perawatan panas sing dirancang kanthi apik (ngasilake kekuatan lan kekerasan permukaan sing dikarepake), saka tes bukti nganti tes mekanik kanggo verifikasi kualitas permukaan & batin.

Rantai link babak SCIC digawe miturut standar China GB / T-12718 lan Keperluan Teknis pabrik, uga standar DIN 22252 utawa GOST 25996 lan spek klien

chain link babak SCIC digunakake kanggo Armored Face Conveyors (AFC), Beam Stage Loaders (BSL), mesin header dalan, plows batu bara lan peralatan liyane sing mbutuhake jinis chain.

Lapisan anti-korosif (contone, galvanisasi sing dicelupake panas) nyebabake sifat mekanik rantai sing mudhun, mula aplikasi lapisan anti-korosif kudu tundhuk karo persetujuan pesenan antarane panuku lan SCIC.

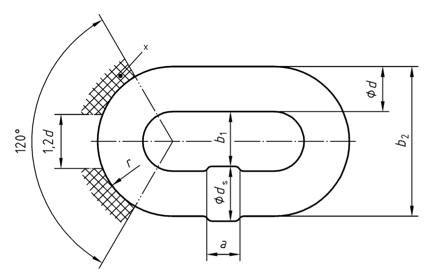

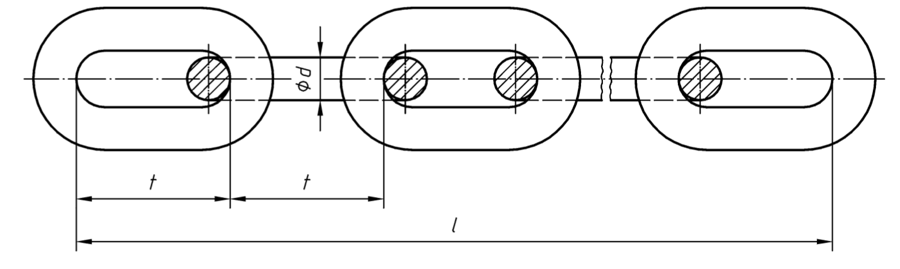

Gambar 1: chain link bunder

Tabel 1: dimensi chain link babak

| ukuran link (opp. Weld) | pitch | jembaré pranala | ukuran las link | bobot unit | ||||

| nominal | toleransi | nominal | toleransi | batin | njaba | diameteripun | dawa | |

| 10 | ± 0.4 | 40 | ± 0,5 | 12 | 34 | 10.8 | 7.1 | 1.9 |

| 14 | ± 0.4 | 50 | ± 0,5 | 17 | 48 | 15 | 10 | 4.0 |

| 18 | ± 0,5 | 64 | ± 0,6 | 21 | 60 | 19.5 | 13 | 6.6 |

| 19 | ± 0,6 | 64.5 | ± 0,6 | 22 | 63 | 20 | 13 | 7.4 |

| 22 | ± 0,7 | 86 | ± 0.9 | 26 | 74 | 23.5 | 15.5 | 9.5 |

| 24 | ± 0,8 | 86 | ± 0.9 | 28 | 79 | 26 | 17 | 11.6 |

| 26 | ± 0,8 | 92 | ± 0.9 | 30 | 86 | 28 | 18 | 13.7 |

| 30 | ± 0.9 | 108 | ± 1.1 | 34 | 98 | 32.5 | 21 | 18.0 |

| 34 | ± 1.0 | 126 | ± 1.3 | 38 | 109 | 36.5 | 23.8 | 22.7 |

| 38 | ± 1.1 | 126 | ± 1.3 | 42 | 121 | 41 | 27 | 30.1 |

| 38 | ± 1.1 | 137 | ± 1.4 | 42 | 121 | 41 | 27 | 29.0 |

| 42 | ± 1.3 | 137 | ± 1.4 | 48 | 137 | 45 | 30 | 36.9 |

| 42 | ± 1.3 | 146 | ± 1.5 | 48 | 137 | 45 | 30 | 36.0 |

| 42 | ± 1.3 | 152 | ± 1.5 | 46 | 133 | 45 | 30 | 35.3 |

| cathetan:Lchain ukuran arger kasedhiya nalika priksaan. | ||||||||

Tabel 2: sifat mekanik chain link bunder

| ukuran chain | kelas chain | pasukan test | elongation ing pasukan test | pasukan putus | elongation ing fraktur | defleksi minimal |

| 10 x 40 | S | 85 | 1.4 | 110 | 14 | 10 |

| SC | 100 | 1.6 | 130 | |||

| SCC | 130 | 1.9 | 160 | |||

| 14 x 50 | S | 150 | 1.4 | 190 | 14 | 14 |

| SC | 200 | 1.6 | 250 | |||

| SCC | 250 | 1.9 | 310 | |||

| 18 x64 | S | 260 | 1.4 | 320 | 14 | 18 |

| SC | 330 | 1.6 | 410 | |||

| SCC | 410 | 1.9 | 510 | |||

| 19 x 64,5 | S | 290 | 1.4 | 360 | 14 | 19 |

| SC | 360 | 1.6 | 450 | |||

| SCC | 450 | 1.9 | 565 | |||

| 22 x86 | S | 380 | 1.4 | 480 | 14 | 22 |

| SC | 490 | 1.6 | 610 | |||

| SCC | 610 | 1.9 | 760 | |||

| 24 x86 | S | 460 | 1.4 | 570 | 14 | 24 |

| SC | 580 | 1.6 | 720 | |||

| SCC | 720 | 1.9 | 900 | |||

| 26 x92 | S | 540 | 1.4 | 670 | 14 | 26 |

| SC | 680 | 1.6 | 850 | |||

| SCC | 850 | 1.9 | 1060 | |||

| 30 x 108 | S | 710 | 1.4 | 890 | 14 | 30 |

| SC | 900 | 1.6 | 1130 | |||

| SCC | 1130 | 1.9 | 1410 | |||

| 34 x 126 | S | 900 | 1.4 | 1140 | 14 | 34 |

| SC | 1160 | 1.6 | 1450 | |||

| SCC | 1450 | 1.9 | 1810 | |||

| 38 x 126 | S | 1130 | 1.4 | 1420 | 14 | 38 |

| SC | 1450 | 1.6 | 1810 | |||

| SCC | 1810 | 1.9 | 2270 | |||

| 42 x 137 | S | 1390 | 1.4 | 1740 | 14 | 42 |

| SC | 1770 | 1.6 | 2220 | |||

| SCC | 2220 | 1.9 | 2770 |